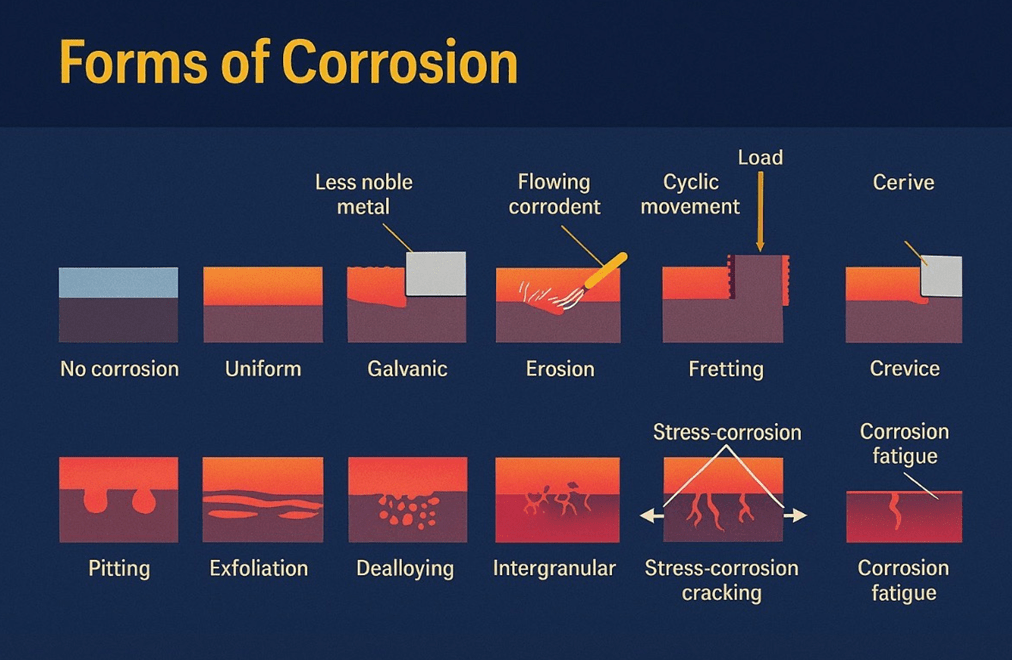

Commercial Standards for Rust Removal/

Before you say, "I'm just a DIYer, this doesn’t apply to me," hear me out – these points will be useful. We often get calls and emails from customers discussing the amount of rust and failing coatings they’ve removed, but the real question is: how much contamination remains on the surface?

As a qualified Paint Inspector, when I assess a surface, I evaluate whether the amount of remaining contamination is acceptable within the specification guidelines. For example, if you're applying a Zinc Rich Epoxy Anode, a quick wire brush won’t suffice. This type of coating requires a bright, blast-cleaned surface for proper adhesion.

Surface preparation standards, especially for steel substrates, are crucial to ensuring the longevity and performance of the coatings applied. The standards Sa, St 2, and St 3 are part of ISO 8501-1, which is widely recognised in the industry. Each standard defines different levels of surface cleanliness achieved through various methods.

Sa Blasting Standards

The "Sa" designation refers to surface preparation achieved through abrasive blasting, as classified in the ISO 8501-1 standard. The levels of Sa blasting are as follows:

-

Sa 1 (Light Blast Cleaning): This is the lowest level of abrasive blasting. Loose mill scale, rust, and foreign matter are removed, but some slight residues and stains from rust or old paint may remain.

-

Sa 2 (Thorough Blast Cleaning): A more thorough level of cleaning, removing most of the mill scale, rust, and contaminants. Some slight staining or shadows may remain, but no significant rust or scale should be left.

-

Sa 2½ (Very Thorough Blast Cleaning): This is the most commonly specified standard. Almost all rust, mill scale, and foreign matter are removed, leaving the surface uniformly grey. This level is often required for high-performance coatings.

-

Sa 3 (Blast Cleaning to Visually Clean Steel): The highest level of cleanliness, removing all rust, scale, stains, and contaminants. The surface should be uniformly metallic in colour.

St 2 and St 3 Mechanical Cleaning Standards

The "St" standards refer to surface preparation achieved through hand and power tool cleaning, as outlined in ISO 8501-1.

-

St 2 (Thorough Hand and Power Tool Cleaning): This involves removing loose mill scale, rust, and poorly adhering paint using hand or power tools such as wire brushes, scrapers, or grinders. After cleaning, the surface should be uniformly clean, though some tightly adhering rust or mill scale may remain. St 2 is suitable for less corrosive environments.

-

St 3 (Very Thorough Hand and Power Tool Cleaning): This requires more rigorous use of the same tools as St 2, resulting in a cleaner, more metallic surface finish. It’s typically needed in more demanding environments where better coating adhesion is essential.

Key Differences:

-

Sa Standards: Achieved through abrasive blasting, these are generally more effective and produce a cleaner surface than the St standards, which use mechanical tools.

-

St Standards: Hand and power tool cleaning is less aggressive than blasting, but St 3 is more thorough than St 2, resulting in a cleaner surface.

In summary:

- Sa 1 to Sa 3: Increasing levels of cleanliness through abrasive blasting, with Sa 3 being the highest.

- St 2 and St 3: Hand and power tool cleaning standards, with St 3 being more thorough than St 2.

These standards are essential for ensuring steel surfaces are properly prepared for painting or coating, which ultimately enhances the durability and performance of the coating.

Visit the Rustbuster Ltd website for more information on Commercial Standards for Rust Removal/