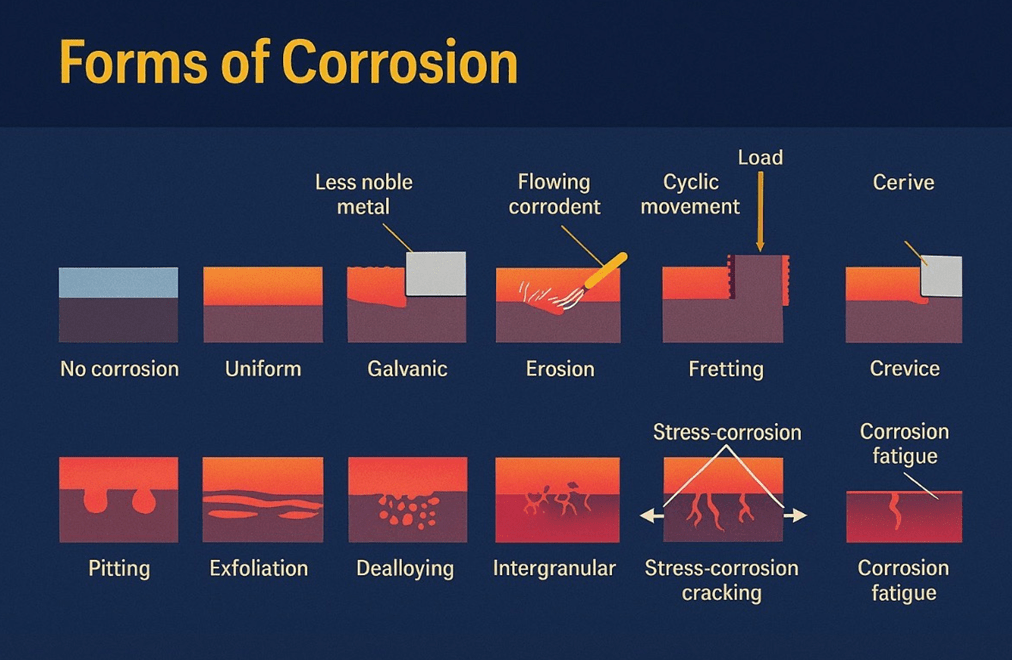

My Epoxy Has Bloomed White! Is This a Problem?

So, you’ve followed the instructions, applied your epoxy coating perfectly, and now… it’s showing a white bloom. You’re probably wondering, “Is this going to be a problem?” In short, it could be. This phenomenon, known as Amine Blush or bloom, happens when ammonium bicarbonate salts form due to changes in humidity and temperature during the epoxy curing process.

This can affect products such as Epoxy Mastic 121, Zinc Epoxy Primer, Custom 421 Epoxy Primer Paint, and Armaguard Rust Protection Paint.

But before you panic and swear off epoxy coatings forever, let’s take a closer look at the issue.

Is It Sticky or Hard? That’s the Important Question

Once the epoxy has fully cured, examine the bloom: is it hard and dry, or sticky compared to the surrounding area? This distinction is crucial, as it determines whether the issue is purely cosmetic or something more serious.

If the bloom is sticky, we could be facing several potential problems:

- Overcoating failure – not ideal when you need to add another layer.

- Aesthetic issues – no one wants a patchy or unsightly finish.

- Decreased stain resistance – spills and stains could be more noticeable and harder to clean.

- Yellowing tendency – like an old newspaper, but far less appealing.

- Softness of the coating – your epoxy shouldn’t feel like a sponge!

- Reduced chemical resistance – weakening the epoxy’s overall durability.

However, if the bloom is hard and matches the surrounding epoxy, the issue is likely just cosmetic—annoying but manageable.

What Should You Do Next?

If the bloom is sticky or soft, unfortunately, you’ll need to remove it and reapply the coating. But if it’s only a visual issue, here’s how you can resolve it:

- Test it: Since amine is alkaline, you can use litmus paper to check if the bloom is still active. A quick science experiment to the rescue!

- Wash it: Clean the surface with a detergent, making sure to rinse thoroughly to avoid any soap residue causing more trouble.

- Abrasive care: If the sticky film remains, gently abrade the surface with a Scotch-Brite or nylex pad. Be careful not to damage the epoxy, especially if you don’t plan to recoat soon.

How Can You Prevent This in the Future?

Avoiding the dreaded bloom is simpler than you might think. Here are a few tips:

- Paint on dry days: Low humidity is your best friend.

- Avoid cold, damp conditions: Especially on foggy winter evenings, unless you're working in a heated space.

- Use a dew point calculator: This handy tool, available on our website, helps you avoid moisture miscalculations. Follow this link to our Dew Point Calculator.

- Mix precisely: Use the exact ratio of component A to B. Guessing isn’t an option—Component B (the hardener) is crucial, so precision is key.

What If You Can’t Avoid Poor Conditions?

If you’re working in less-than-ideal conditions—such as maintenance projects or during shutdowns—don’t despair! Contact our technical department to learn about our full range of MCU moisture-curing urethanes. These coatings are specially designed to perform in cold and damp environments, so you can continue your work stress-free, regardless of the weather.

In conclusion, whether the bloom is sticky, soft, or simply unsightly, epoxy bloom doesn’t have to be a disaster. With a bit of know-how and the right approach, you can tackle it head-on—like a true epoxy expert!

Visit the Rustbuster Ltd website for more information on My Epoxy Has Bloomed White! Is This a Problem?