Tech Line Coatings: Pioneers in Thin-Film Ceramic Excellence

With origins in aerospace technology—including coatings first developed for the X-30 Space Plane fuselage—Tech Line Coatings has spent more than 30 years perfecting high-performance surface solutions for automotive, industrial, and commercial use. Headquartered in Tennessee, the company now works with a global network of over 1,000 applicators.

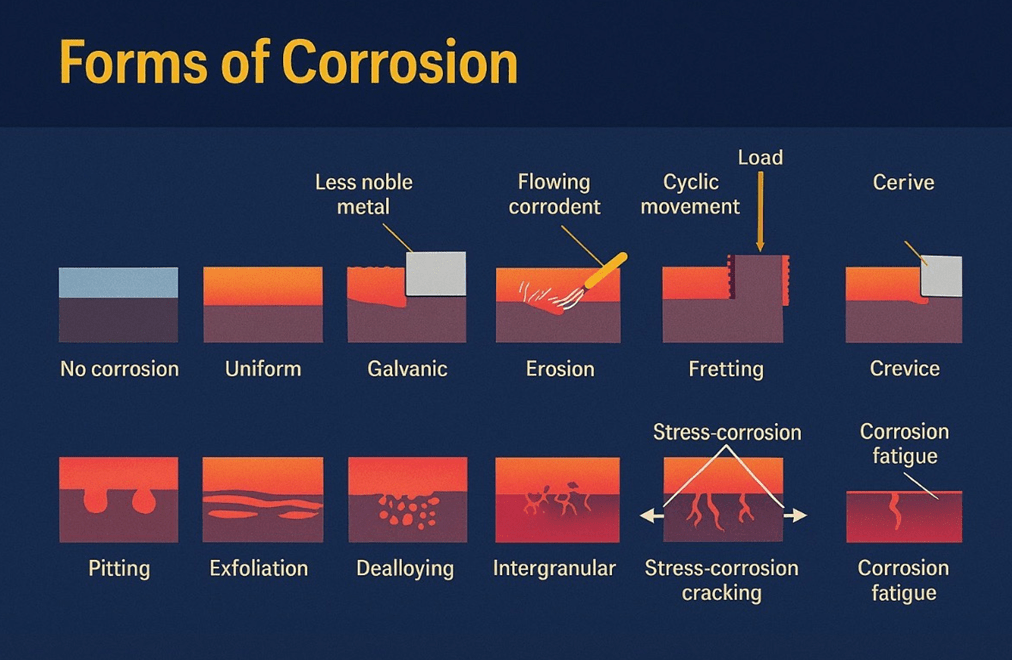

The brand is recognised for its thin-film ceramic coatings, which withstand extreme heat (up to 2,000 °F / 1,093 °C) while offering thermal management, corrosion resistance, lubrication, and striking aesthetics. The product portfolio ranges from CermaKrome metallic finishes to thermal dispersants and powder coatings.

Spotlight: Black Satin™ (Part #BHK)

Black Satin™ is widely regarded as Tech Line’s flagship product. This ceramic-reinforced, satin-black coating is purpose-built for the toughest exhaust environments.

-

Extreme Temperature Resistance – Survives substrate temperatures exceeding 2,000 °F, with long-term stability up to around 1,600 °F.

-

Thermal Barrier Performance – Reduces radiant heat, lowers under-bonnet temperatures, improves exhaust gas velocity, and can contribute to gains in horsepower and torque.

-

Tuning Aid – Shifts in colour with temperature provide a visual guide to heat levels, a useful aid for engine tuning.

-

Flexible Application and Curing – Can be air-dried and cured using exhaust heat, or oven-cured at 700–750 °F for one hour to achieve maximum resistance to chemicals, moisture, and corrosion.

-

Durable and Reliable – Delivers outstanding adhesion (ASTM tape test 5B), pencil hardness of 8+, and retains flexibility to endure thermal cycling and shock.

Application Guide

-

Preparation – Grit-blast with 120-grit aluminium oxide (avoid glass bead). Clean thoroughly with acetone or lacquer thinner.

-

Coating – Apply one thin layer (0.001–0.0015″) with spray equipment. Multiple passes can weaken adhesion.

-

Curing – Allow to air-dry before curing with exhaust heat or oven per recommendations (500 °F for partial cure, 700+ °F for full cure).

-

Caution – Initial high exhaust temperatures can affect the resin, so ensure engine tuning is correct beforehand.

-

Compatibility – Can be applied over base coatings such as PrevCor, MCS, or HHBK for improved thermal and corrosion protection.

Why Black Satin™?

-

Performance – Reduces radiant heat for measurable improvements in efficiency.

-

Durability – Provides long-lasting resistance to salt, water, fuel, and solvents—particularly when fully cured.

-

Visual Appeal – Delivers a classic satin-black finish with functional thermal benefits.

-

Proven Reliability – Used by OEMs, industrial clients, and performance specialists worldwide.

Availability

Black Satin™ comes in sizes from 4 oz tins—ideal for small jobs like short headers—to gallon cans for professional use. It is supplied spray-ready, requiring no thinning. Simply shake, spray, cure, and it’s ready to perform.

Conclusion

Tech Line Coatings combines aerospace heritage with decades of automotive expertise, setting new standards in ceramic thin-film technology. Black Satin™ exemplifies this, offering extreme heat resistance, corrosion protection, improved performance, and a refined satin finish. Whether for headers, turbos, or display pieces, it provides the ideal balance of durability, practicality, and style.

Visit the Rustbuster Ltd website for more information on Tech Line Coatings: Pioneers in Thin-Film Ceramic Excellence