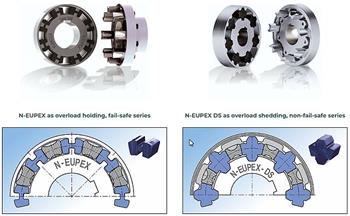

Torsionally Flexible Claw Couplings

N-EUPEX® rated torque: up to 85,000 Nm, ATEX compliant, Complies with the current ATEX Directive for: II 2G Ex h IIC T6 ... T4 Gb X II 2D Ex h IIIC T85 °C ... 110 °C Db X I M2 Ex h Mb X. N-EUPEX® flexible shaft couplings are designed on a modular principle and have a very simple construction. N-EUPEX types are made up of sub-assemblies to suit requirements. The couplings are assembled by simply fitting the coupling halves together. Wear is restricted to the elastomer elements, which must be replaced at the end of their service life. Depending on type, the elastomer elements can be changed without moving the coupled machines. The coupling parts are readily available from stock and are mostly finish-machined, i.e. with finished bore, keyway, set screw and balancing. Please note that if the couplings are finished machined / bored and keyed in the jbj Techniques machine shop, the couplings will be supplied un-balanced, unless specifically requested. The N-EUPEX coupling is available as a catalogue standard in 23 sizes with a rated torque up to 85,000 Nm. The coupling is suitable for use at ambient temperatures of between -30°C and +80°C. By using alternative elastomer elements, the permissible ambient temperature range can be extended to between -50°C and +100°C. Generally, the coupling is used to connect the motor to the gear unit input shaft. The coupling is especially suitable for drives with uniform to average dynamic loads. Additional variations: » Adapters and hubs: Grey cast iron EN-GJL-250 » Brake disks: EN-GJS-400 spheroidal graphite cast iron or S355J2G3 steel » Brake drums: Grey cast iron EN-GJL-250 » Low-temperature application: Shock loads in the drive caused by e.g. starting of drives with large masses to be accelerated (e.g. in fan drives) result in high component loads, particularly at low temperatures. For such applications a particularly robust coupling series must be selected. Note about ATEX compliance Both series are ATEX certificated, but importantly it must be noted that the N-Eupex coupling is ATEX compliant as long as the coupling is operated in accordance with the installation, operation and maintenance manual. More importantly the maintenance aspect, replacing the elastomers prior to failure. This is due to the fail-safe design allowing torque transmission should the elastomers fail. If complete ATEX safety is required, without needing to adhere to the N-Eupex maintenance requirements, then the N-Eupex DS is the coupling to use. A new type, N-EUPEX DK, added to the modular principle of N-EUPEX and the performance & bore capacity of all types increased. Double-cardanic system. With the new double-cardanic design, the coupling compensates for not only a greater range of shaft angle offsets, but also a considerably greater radial offset so that shaft ends can be connected in a manner that offers the drive greater protection. With this two-joint version, compensation for radial offset that occurs between the shaft ends is enabled by a corresponding angle of inclination in the elastomer joints. This increases the range of possible radial offset by more than a multiple of four. Especially with pump applications, shaft ends that are not 100% in alignment present a significant problem. In this case, the N-EUPEX DK provides a solution for many problems because, depending on the coupling length and size, it enables compensation for a radial offset of up to 3 millimetres. Furthermore, in contrast to the previous N-EUPEX, the new coupling type "DK" makes use of not just one, but two series of elastomer elements, which guarantees increased damping over the entire drive train. In addition, due to the double-cardanic design, significantly lower restoring forces are generated. The high ratio of shaft and joint clearance also decreases the restoring forces. Depending on size, offset and installation dimensions, the restoring forces decrease by more than half. The result is a lower load on the shafts along with a lower load on the bearings. This is advantageous especially with thinner shafts, which can be damaged due to the wrong coupling design or improper installation, even up to the breakage point. The spacer, made of aluminum with a joined pocket part made of gray cast iron, comes in standard increments for shaft spacing from 100 mm to 250 mm, so its length can be adapted to the customer's design.Visit the jbj Techniques Limited website for more information on Torsionally Flexible Claw Couplings