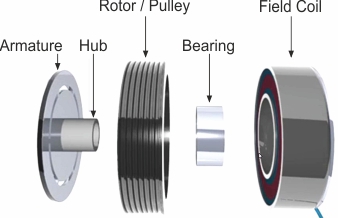

Electromagnetic clutches

General description of electromagnetic clutches These are flange mounted, normally a two piece construction clutch typically mounted directly on to the pump. Solid forged rotor. A one piece solid forged rotor means no chance of internal parts separation. The rotors also have an even wall thickness around the coil which gives optimum flux distribution, maximizing torque. electromagnetic clutch photograph Different coil voltages available. Although 12 volt is the most common, 24 volts can also be made available. Depending upon the quantity, other specialty voltages can be made. High temperature, longer life grease. All models include our special long life grease which has shown a significant improvement in life over other standard high temperature greases. E-coating. Where possible, all parts in the clutch are e-coated to give maximum corrosion protection. High temperature epoxy coil. To help prevent failure from both vibration and outside contaminants, all coils are sealed in the coil shell with a high temperature epoxy coating. Forged machined pulley. All models in this section use a heavy duty machined pulley. A stronger pulley resists damage due to abusive environments.Visit the jbj Techniques Limited website for more information on Electromagnetic clutches