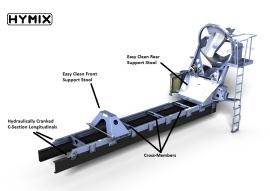

Standard Mixer Drum

Put quality stone into a tipper and you will deliver quality stone to the job site. The quality of delivered concrete however is influenced by the performance of your mixer drum. There is very little you can do about traffic, but a Rapid Discharge Drum will discharge faster saving you time on site. As well as saving time, turning the drum less uses less fuel. This is an equation that Hymix understands well. Hymix Drums have been earning more and saving more since the introduction of their Rapid Discharge technology in 1992. The P-Series drum respects this equation with the same blade configuration. More work at lower cost means more profit! Thick and wide capping strip protects the blades which are a full 450mm high in the mix zone. The obvious change to the drum has been the re-introduction of a dished and flanged end replacing rolled and welded end. This is better suited to modern trucks as it can cope with more powerful engines and more efficient braking systems. Importantly, in fabrication it provides a platform to achieve a more consistent driving flange installation helping your gearbox to last longer.Visit the Hymix website for more information on Standard Mixer Drum